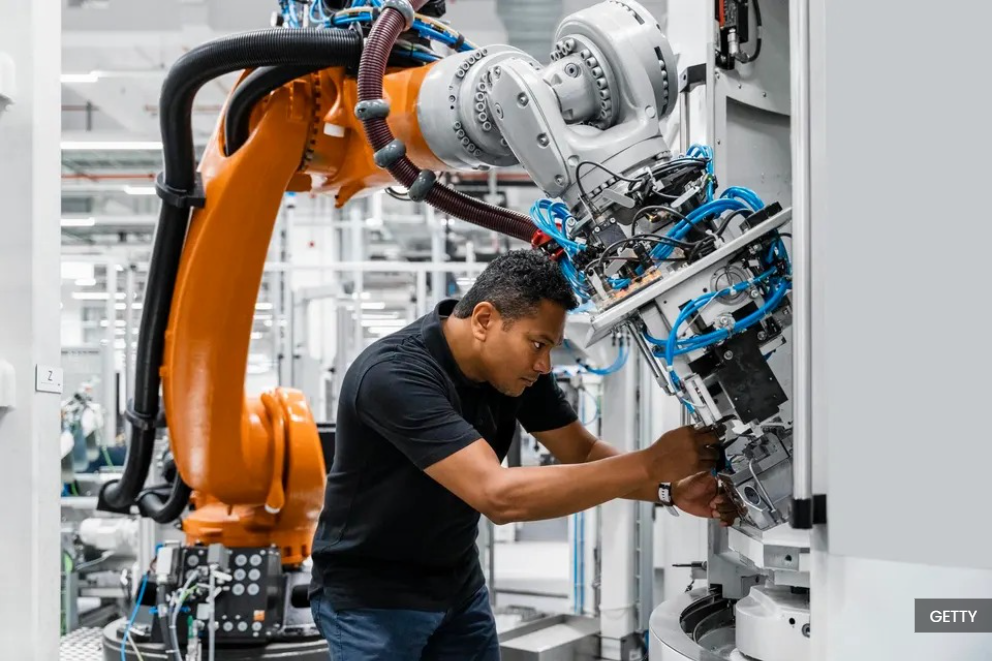

KUALA LUMPUR, Nov 13 — Experts have urged Malaysia’s manufacturing sector to adopt a people-centred, data-driven approach to digitalisation in order to sustain progress under Industry 4.0.

They said this transformation should start small, gradually integrate artificial intelligence (AI) and automation, and strengthen collaboration between industry, government, and academia.

Speaking at the Building the Next Generation of Intelligent Manufacturers forum, held in conjunction with the Selangor Techsphere Summit 2025 yesterday, Unbound head of technology Natalie Loi said successful digitalisation requires a balance between technology and human input.

“Technology alone cannot create purpose. It cannot solve production issues based on its own understanding. Only humans can define what the most ideal outcome should be,” she said.

Drawing from her experience working with manufacturers, Loi said her team helps companies streamline production through AI, computer vision, and machine learning, from detecting defects to predicting energy consumption or equipment failure.

She stressed that digital adoption should be incremental, not abrupt.

“You cannot just revamp an entire system that has been in place for 20 or 30 years. That’s not doable (and is) unethical and unsustainable. Our approach is step by step. We monitor systems, collect data, simulate outcomes, then implement improvements.

“Radical change may sound exciting, but it risks breaking the whole production line,” she said, adding that digitalisation should involve the workforce rather than replace it.

Loi also highlighted the importance of collaboration between academia and industry to commercialise research outcomes and translate findings into tangible industrial benefits.

She also likened the collaboration between technology developers, manufacturers, and researchers to building a complete human system.

“We (tech developers) build the brains, manufacturers build the body, and academics validate that it’s viable, sustainable, and scalable,” she said.

Asking the right questions

Malaysia’s factories must first focus on people, culture, and process alignment before introducing large-scale digitalisation or automation, said SMART Modular Technologies head of manufacturing and lean factory manager Sarvanasivan Ganesan.

Sharing his company’s experience leading lean digital transformation at SMART Modular’s Penang facility, Sarvanasivan said that Industry 4.0 adoption should start with understanding a factory’s needs rather than adopting existing solutions.

“A machine is just a machine. (What’s important is) how you adapt. Before you bring in any new technology, you must ask, what kind of digitalisation are you really trying to achieve?”

Sarvanasivan said successful transformation depends on three main pillars, namely cultural, lean, and digital, which must progress in tandem.

“The first pillar is culture, because people often fear that digitalisation means job cuts. We need to build a culture that helps workers understand change is necessary and beneficial.

“Lean transformation then looks at reducing waste, while digital transformation uses data and technology to streamline those processes.”

Sarvanasivan said his factory’s approach mirrors that of many advanced manufacturers, which started small, and scaling up only when results are measurable and sustainable.

He shared several success stories, including machine-to-machine integration projects that reduced production changeover time from 65 minutes to just 15 seconds through the use of open Application Programming Interface (API) communication systems.

He also stressed the importance of collaboration between industry and academia, particularly with local universities, to nurture the next generation of engineers and researchers skilled in Industry 4.0 technologies.

“Industry has to play a part with colleges and universities so that students can experience real manufacturing environments. Industry 4.0 is not just a word, it has to be cultivated and embedded in students so it becomes part of their journey.

“Over the next 10 to 20 years, AI will take us to a different dimension. If we don’t start adapting now, we will fall behind,” Sarvanasivan said.